ABOUT US

PRODUCT DEVELOPMENT

To meet the various requirements from each Customer,

we are exploiting the raw material resources not only in Vietnam but also in China, Thailand, Indonesia, Japan, Korea and ect. to ensure the stable supply.

Furthermore, we also focus on researching the new-added values to those materials.

PRODUCTION SYSTEM

1

Raw Materials

Many types and colors of yarn are used to produce the socks.

From natural fiber such as cotton and linen to synthetic fiber like nylon and polyester are available in stock.

2

Knitting

By using knitting machine, we design and form various socks.

Sophisticated techniques are absolutely necessary to deliver a perfect fit and feel for a wonderful sock experience.

3

Toe Linking

After knitting process, the socks are not finished products yet.

They need to be sent to the next process for toe linking.

4

Setting

To make the good shape of socks, all socks are set on the metal boarding forms and are being sent to a high temperature and pressurized steam in the boarding machine.

5

Pairing

In this section, all socks must be inspected to get the dirt and lint off.

and then pairing is completed.

6

Needle Checking,Packing

Finally, all products have to be sent through the needle detector for safety packing.

SPECIAL PROCESSING

Laundry Machine

Any dyeing chemical substances will be removed out of from the socks surface after washing process

Napping Machine

The inner side of socks shall go through the napping machine to make the raised nap.

The nap makes the fabric feel softer and traps air that serves as insulation.

Logo Printing Machine

Using this machine to print the logos on socks

Anti-Slip Silicone Printing Machine

Using this machine to print the anti-slip silicone dottings on socks。

Embroidery Machine

Using this machine to embroider brand logos on socks

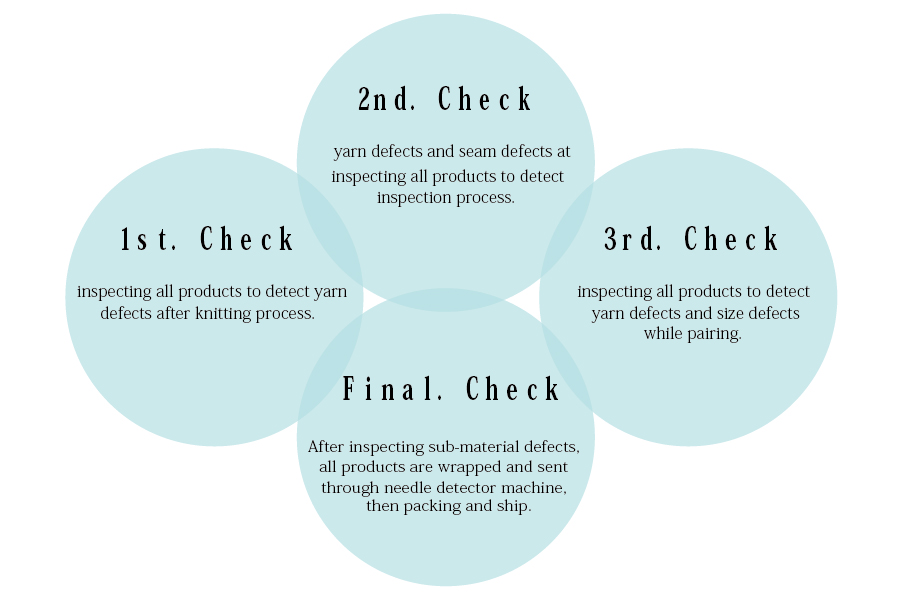

QUALITY ASSURANCE

To provide Customers with safety and high quality products,

Every products are being inspected through out below four processes.